Release time:2025-03-28 15:26:52

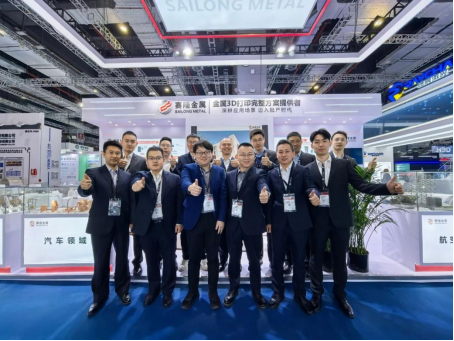

From March 17th to 19th, the Asian additive manufacturing industry event - 2025 TCT ASIA was grandly launched at the National Convention and Exhibition Center (Shanghai). With the theme of "Deepening application scenarios, entering the batch production era", Xi 'an sailong brought metal additive manufacturing batch production solutions, electron beam 3D printing equipment and industrial batch production application cases to booth 7K55 in Hall 7.1, and released new products of SLMP ™ plasma system powder equipment, fully demonstrating its technological innovation achievements in the industrial application of additive manufacturing.

01 Electron beam additive manufacturing batch production solutions started, and joined hands with industry users to build industrial intelligent ecology

In the field of medical orthopaedics, Xi'an Sailong demonstrated the batch production application case of electron beam 3D printing standardized orthopedic implants. Taking T200 electron beam 3D printing equipment as an example, 288 pieces of acetabular cup, 126 pieces of femoral shaft, more than 3000 pieces of interbody fusion device and 96 pieces of tibial platform can be produced in a single furnace, and the printing time is about 120h, providing users with mass, high efficiency and low cost manufacturing solutions for orthopedic implants. The company has invested more than 40 sets of electronic beam 3D printing equipment with independent intellectual property rights, built an orthopedic implant production line with an annual capacity of more than 100,000 pieces, and delivered more than 50,000 pieces in 2024, helping the industrialization of additive manufacturing orthopedic implants.

In the automotive industry, Xi'an Sailong demonstrated a batch production application case of electron beam 3D printing copper materials. Taking Y150 electron beam 3D printing equipment as an example, 20 pure copper induction coils of ball cage type can be produced in a single furnace, and the printing time is about 36h. The company has built a 3D printing induction coil production line with an annual capacity of more than 20,000 pieces, providing users with 3D printing copper material solutions that reduce cost and increase efficiency.

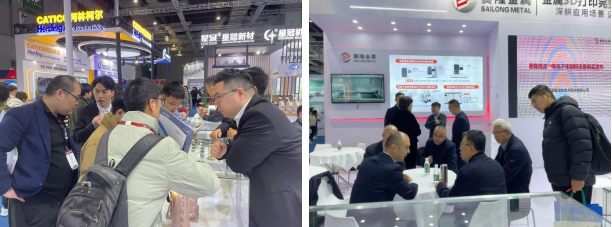

02 SLMP™ plasma powder equipment new release detonated the audience, promote resource recycling and energy saving and carbon reduction

At the exhibition site, Xi'an Sailong released the first commercial microwave plasma powder equipment independently developed in China, which realized the research and development and production of micron metal and non-metal powder spheroidization and nano powder, attracting many industry experts and customers for consultation and discussion.

Xi'an Sailong deeply integrates the core concepts of flexible manufacturing, low carbon emission reduction and recycling, breaks through high-power microwave heating technology and a variety of air pressure accurate regulation technology, and independently develops two high-power microwave plasma generators of 15kW and 25kW. And equipped with efficient powder collection and classification system, cooling system, feeding system, high precision temperature control system and gas control system. The equipment can be equipped with spherical powder making and nano powder making process modules, supporting users to formulate production plans as required, and can control the particle size distribution, sphericity and chemical composition of powder materials, to meet the differentiated demand for high-quality powder in additive manufacturing, energy storage, semiconductor, biomedical, aerospace and other fields.

The spheroidization module unit of the complete set of devices has achieved the preparation of spherical powders of 5 ~ 500μm titanium alloy, iron base alloy, refractory metal and alloy, superalloy, high-temperature ceramics and other materials, and the nano powder module unit has achieved the preparation of nano spherical powders of 10 ~ 500nm Si, Cu, Ni, carbide, nitriding, oxide and other nanoparticles.

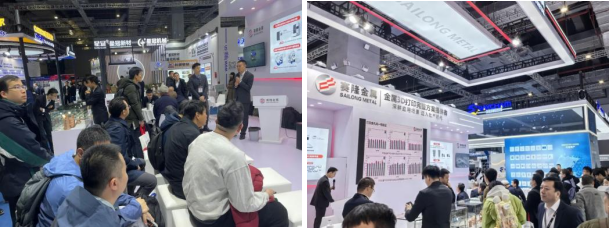

03 Wonderful speech, in-depth discussion of process technology + application scenarios

During the exhibition, a number of presentations were held around additive manufacturing technology innovation and typical application cases in the industry. Including "New release of microwave plasma powder equipment", "Mass Additive Manufacturing of standardized orthopedic implants by Powder bed electron beam melting", "Research and Application of Powder bed electron beam additive Manufacturing of difficult-to-process metal parts", "Research progress of high energy density plasma rotating electrode atomization powder technology and equipment", etc., attracting many on-site audiences to stop and interact. Discuss the new development of additive manufacturing.

Time harnesses seiko and innovation never stops. The 2025 TCT Asia Exhibition came to a successful end, Xi'an Sailong will continue to deeply cultivate the application scenario, take the user as the center, and promote the industrial application of 3D printing to a new height.

By Telephone

Contact

TOP