Release time:2023-04-20 09:35:39

Selective Electron Beam Melting (SEBM) is a unique metal additive manufacturing technology. It has the characteristics of high energy density, fast production efficiency, low forming stress and no pollution in vacuum environment. SEBM technology is especially suitable for the rapid forming of Titanium and Titanium alloys, refractory metals (Tungsten, Molybdenum, Tantalum, Niobium), brittle materials (Titanium Aluminum alloy) and high reflective materials such as Copper and Aurum.

On April 20,2023, Antarctic Bear knew that Xi'an Sailong took the lead in launching a commercial electron beam metal 3D printer equipped with an indirectly heated tungsten cathode electron gun, and achieved mass sales. Sailong adopted the principle of indirectly heated cathode, combined with SEBM technology requirements to carry out structural innovation and functional expansion, developed indirectly heated electron gun with high-power, high-precision,long-life and low-cost, and realized the independent control of core devices.

△SEBM printed orthopedic implants of Titanium alloys

The development history of SEBM electron gun at home and abroad

Due to the high-tech threshold of the equipment, there are few enterprises at home and abroad with the manufacturing capacity of commercial electron beam 3D printing equipment. The electron gun is the core of SEBM equipment, which determines the build size, printing accuracy and the quality and performance of the formed parts. Different from the special laser of selective laser melting (SLM) equipment, there is no commercial product of special electron gun at home and abroad. Each SEBM equipment manufacturer must first develop a special electron gun before developing the equipment.

In recent years, the United States, China, Japan, Sweden, the United Kingdom and other countries have increased the research and development of special electron guns for SEBM equipment, and have successively developed direct-heated electron guns with tungsten and single crystal LaB6 as cathodes. This is the first generation of commercial SEBM equipment. It has the advantages of low cost and stable performance. However, it has the disadvantages of short life (< 100h) and large beam spot diameter (200-300 μm) under high power.

In order to solve this problem, relevant enterprises have introduced the second generation of direct-heated electron gun with LaB6 cathode. Compared with tungsten cathode, LaB6 cathode has the advantages of long life (> 500 h), high power (6kW) and small beam spot diameter (140μm). However, the cathode cost of this material is high, and the single price is between 10,000-15,000 Yuan. In addition, the LaB6 cathode is easy to pollute and has a high requirement for vacuum (10-4 Pa), which also increases the use and maintenance cost of the electron gun. For the pursuit of low-cost industrial-scale production, the direct-heating LaB6 cathode is more luxurious. Therefore, how to solve the contradiction between the power, life, accuracy and cost of the electron gun is the bottleneck that restricts the development of SEBM equipment and technology.

△Direct-heated electron gun

Sailong commercial SEBM equipment equipped with indirectly heated tungsten cathode electron gun

As one of the earliest domestic enterprises to develop commercial SEBM equipment, Sailong took the lead in the international launch of a commercial SEBM equipment equipped with tungsten cathode electron gun.

In order to avoid the problem of direct-heated electron gun, Sailong's technical team used tungsten as the cathode material, adopted the principle of indirectly heated cathode, and carried out structural innovation and functional expansion in combination with SEBM technology and process requirements. A low-cost indirectly heated electron gun with high power, high precision and long life was developed, and the core devices were independently controllable.

It is reported that the power of the indirectly-heated electron gun can reach up to 6kW, which can quickly preheat the powder bed to 1300℃ and greatly improve the printing efficiency. The overall cathode assembly of the electron gun has a service life of more than 500 hours, which is equivalent to the actual use time of the direct-heated LaB6 cathode, and meets the manufacturing requirements of large-size parts or long-term stacking printing. By changing the cross-section characteristics of the cathode, the beam spot diameter under high power can be controlled, and the accurate scanning of the beam spot diameter (<100μm) in a wide range can be realized, which meet the high-precision manufacturing requirements of the parts. Both the cathode and the auxiliary cathode of the electron gun are made of tungsten material, which has good wear resistance. The cost is less than 30% of the direct-heated LaB6 cathode, which meet the low-cost and mass production demand of parts.

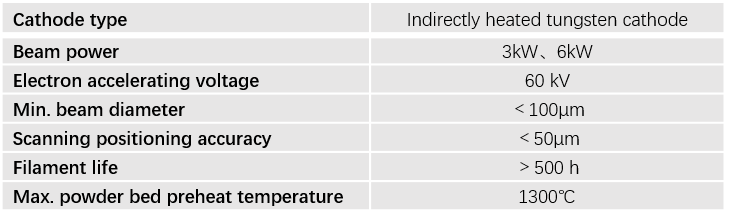

△ Main parameters of indirectly-heated electron gun

For different application scenarios, Sailong has launched a series of SEBM equipment with different build sizes and indirectly heated electron guns with different powers, such as Y150 Plus (beam power 3kW, build size 170×170×180mm), T200(beam power 6kW, build size 200×200×450mm), H400(beam power 6kW, build size 400×400×400mm). The related equipment has successfully realized the high-precision, low-cost and mass manufacturing of complex parts such as medical Titanium alloy, Titanium aluminum and pure Copper. Taking T200 SEBM equipment as an example, it can produce 288 Titanium alloy acetabular cups in a single furnace (within 100 hours). The forming accuracy of the porous part is less than 0.1mm, and the manufacturing cost of a single acetabular cup is less than 100 Yuan.

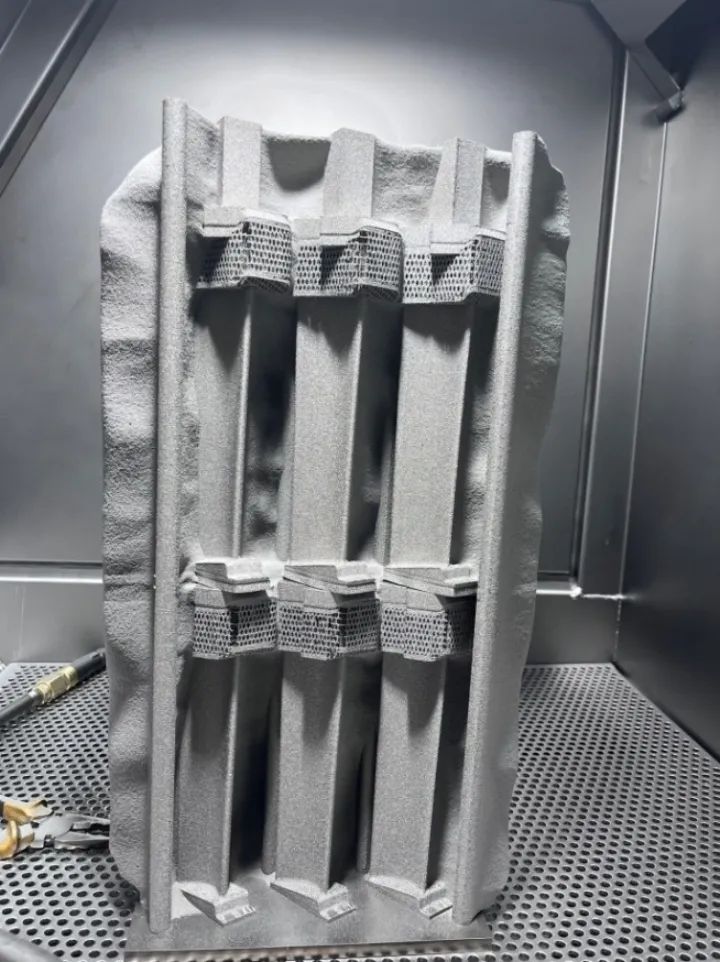

△ Sailong SEBM equipment with indirectly-heated electron gun

△ SEBM printed Titanium alloy acetabular cups

△SEBM printed intervertebral body fusion devices with high precision

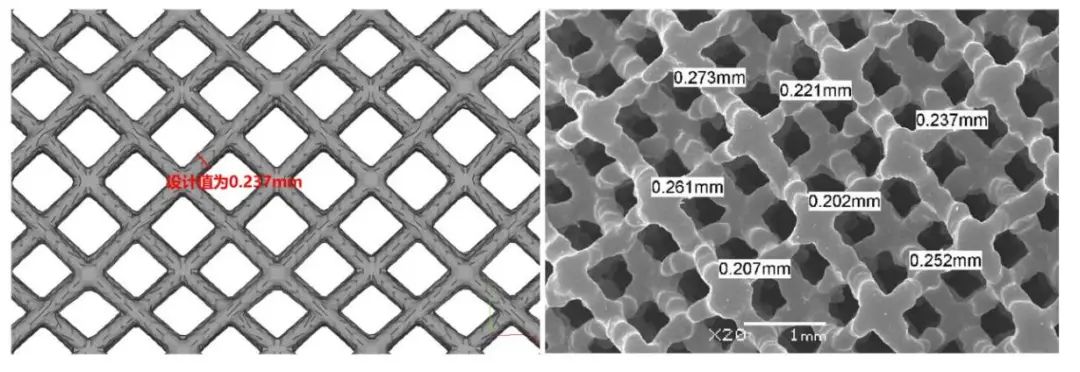

△SEBM printed porous Titanium alloy surface design(left) and SEM images(right)

△SEBM printed TiAl blades

Sailong's technical breakthrough in indirectly heated electron gun marks that China has made important progress in the core devices of SEBM equipment, and has gradually established a technological system of independent control and innovation, which provide a strong guarantee for the large-size application of this technology in related industries.

From:Antarctic bear 3D printing media

By Telephone

Contact

TOP